It’s been called the “miracle house”, surviving one of the deadliest fires to hit LA in recent history. Most of the stories surrounding wildfires are about our eroding environment, government reaction, and humanitarian efforts. It’s rare that we see a building (let alone building science) be the hero.

In this post we dive into:

What is Passive House?

What makes Passive House design more fire resilient?

Should we consider Passive House when rebuilding in areas of high fire risk?

What is Passive House?

Passive House or Passivhaus is a building efficiency standard that reduces the building’s ecological footprint while improving indoor comfort. It originated in Germany in the 1990s and is now a globally recognized model for construction. Broadly, the standard involves 5 core components:

Super-insulation

Air-tightness

High performance windows

Mechanical ventilation with heat recovery

Thermal bridge free

The main selling point of Passive House is a 90% reduction in heating and cooling compared to conventional buildings while maintaining consistent and comfortable indoor temperatures. On top of that, indoor air quality is improved through air-tight insulation and continuous filtered ventilation. Simply, keep more of the outside out and the inside in.

Passive House is deeply rooted in building science. Its principles rise out of a comprehensive approach considering materials, details, building orientation, and modern methods to create a building system that achieves a high level of efficiency and comfort while reducing operational impact on the environment.

Super Insulation

Despite the feeling of separation, there is a lot of the outside leaking into our buildings. I once caved and bought a heater/dehumidifier after many seeping cold nights when I worked in London as a youngling. The British cold creeps in through the old walls and doors.

Insulation is the stuff that goes in between your walls, floor, and ceilings to reduce temperature and moisture transfer. It does so by stopping transfer between the outside and inside through convection, radiation, and conduction.

Air convection is the transfer of heat through moving air. Materials like mineral wool or fiberglass trap air, preventing it from moving and carrying heat.

Radiant transfer is through electromagnetic waves, without direct contact or through a medium. Some insulation materials have a reflective coating to block radiant transfer.

Conduction is the transfer of heat through direct contact between materials. While air is a poor conductor, solid insulation further reduces transfer by minimizing contact.

Passive House standards typically require materials with R-values that are 2–3 times higher than those used in standard construction. The R value is a measure of a material’s ability to resist heat transfer. A 1 inch airspace has the same R value as 8 inches of concrete at R-1. Fiberglass insulation is typically R-11. The greater a material’s R value, the better it is at maintaining indoor temperature.

Assembly | Conventional | Passive House

-------------------------------------------------

Walls | R-13–20 | R-40–60

Roofs | R-30–38 | R-60–80

Foundations/Slabs | R-10–15 | R-30–50We tend to see higher R values used in newer homes and colder climates. In balmy LA, the typical wall R value is R-13-20, 1/3 to 1/2 the Passive House minimum.

Air Tightness

Air that transfers between the outside and inside in a leaky building also transfer temperature. Feel around your doors and windows and you’ll sometimes feel a small flow of air (especially if the outside temperature is dramatically different). Air leakage also brings in outside air particles, which is particularly problematic during a fire.

Air tightness is tested through a blower door test. A fan is mounted on an exterior door frame and blows air in or out to pressurize or depressurize the house. Pressure sensors monitor the air pressure difference between the inside and outside. The result is given as ACH50 (Air Changes per Hour at 50 Pascals), measuring how many times the home’s air is replaced in an hour due to leaks. Passive House requires an ACH50 less than or equal to 0.6. The typical home has an ACH50 of 5-10, 10-20x the Passive House standard.

Passive House design achieves air-tightness through a continuous air-tight barrier, often drawn as a red line on section drawings to emphasize that it’s unbroken. We can’t live in a place we can’t get into, so penetrations like doors, windows, pipes will of course break our barrier. Minimizing and properly sealing penetrations is essential in Passive House design, and part of the reason why high performance windows are a key design principle.

High Performance Windows

By now, you should be sensing a theme. High performance windows are engineered to minimize heat transfer. A view to the outside is non-negotiable.

Passive House usually requires a U-value of less than 0.8 watts per square meter per degree Celsius (W/m²K). U-value measures thermal transmittance, with a lower value indicating better insulation performance. U-value is used for assemblies like windows or doors while an R-value measures the thermal resistance of a solid materials in walls, floors, and roofs. R and U values are reciprocals of each other. R values are additive for materials in a series like layers in a wall. Assembly components cannot simply be added and an R value must be calculated across the entire assembly.

Triple pane windows are usually used for Passive House, whereas typical windows are single or double. More panes contribute to lower U values by encapsulating more air spaces, which have lower thermal conductivity than glass. To further reduce transmittance, these air spaces may be filled with argon or krypton rather than plain air. To counter radiant heat, low-E coatings are applied to one or more of the panes. The coating reflects heat rather than allowing it to pass through. More panes also allow thermal breaks in the framing, minimizing heat transfer through the frame itself. Remember, U-values measure the whole assembly, so every component must do its part.

Mechanical Ventilation With Heat Recovery

With all the focus on a continuous, air-tight, low thermal transmittance barrier between the inside and outside, we still need to be able to move fresh air in and stale air out.

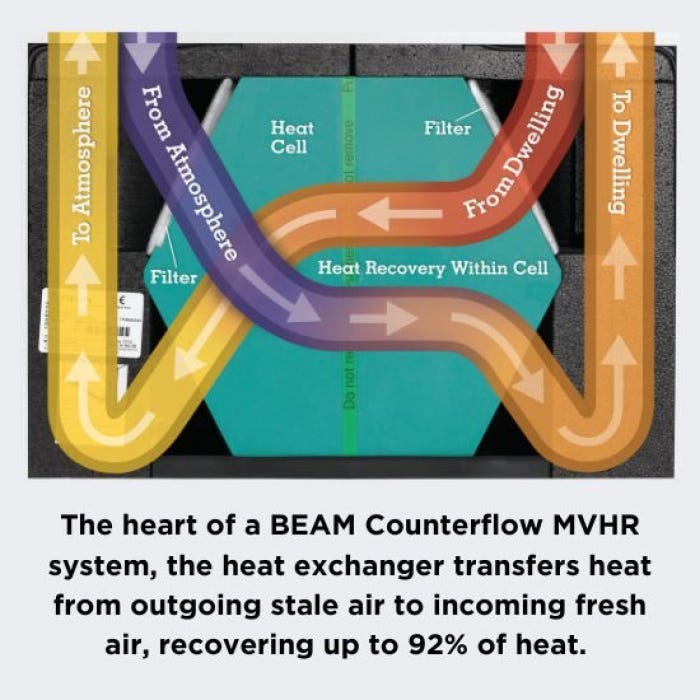

Passive House uses Mechanical Ventilation with Heat Recovery (MVHR) systems which can recover 90% of the heat from outgoing air and transfer it to incoming fresh air. Whereas traditional HVAC is focused on heating and cooling interior air, MVHR is primarily focused on ventilation. This improves indoor air quality by maintaining a constant supply of filtered fresh air.

Indoor air quality came crashing into the public conscious during the 2020 COVID-19 pandemic. However, indoor air quality is vital beyond reducing the spread of airborne diseases. Exposure to high concentrations of indoor carbon dioxide can impair cognitive function, including response times and ability to focus. Exposure to pollutants can also cause respiratory issues, cardiovascular risks, as well as a variety of other adverse health effects.

An MVHR system exchanges stale and polluted indoor air from bathrooms and kitchens with fresh outdoor air blown into other living spaces. The efficiency of the heat exchanger is essential to allow fresh air in without requiring extra conditioning for indoor comfort, which would otherwise diminish the effectiveness of the air-tight low heat transmittance barrier.

Thermal Bridge Free

Materials can convey heat, a lesson quickly learned by touching the handle of a hot pot. Buildings are no different. The metal window casing that feels cold in winter is shedding interior heat, even if air-tight.

A thermal bridge is an area where there is significant heat transfer compared to surrounding materials. This can happen when a material of high thermal conductivity penetrates the insulation layer, creating a pathway for heat to easily escape. Thermal bridges usually occur at junctions, penetrations, and transitions in walls, floors, and roofs. Not only do thermal bridges increase heat loss, they can also create issues like molding due to condensation.

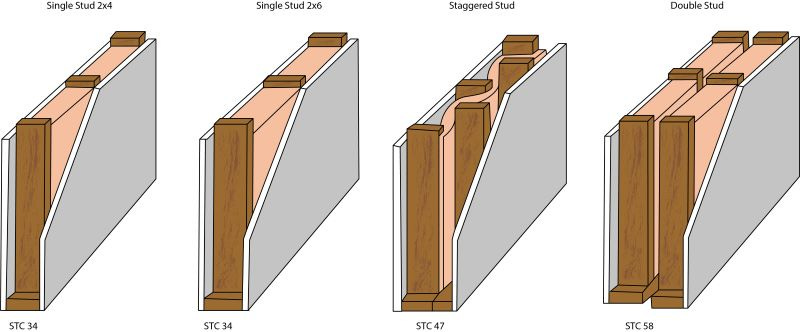

Thermal bridges are mitigated by designing thermal breaks into details and assemblies. Thermal breaks can be materials or gaps that interrupt the conductive heat flow path. An example of this is stagger stud construction, which separates interior and exterior studs. The staggering creates a thermal break for the studs, preventing them from becoming thermal bridges while allowing a continuous layer of insulation in the wall.

What Makes Passive House Design Fire Resilient?

You might be wondering why we haven’t talked about fire resilience in Passive House. The main reason is that Passive House design is not designed primarily for fire resilience, but many of its principles significantly improve a home's ability to withstand fire. The main goals of Passive House are energy efficiency, comfort, and sustainability. A home that’s designed with these principles just happens to also be much more fire resilient.

How Fires Ignite a Home

Wildfires can penetrate and ignite a home through several pathways.

Direct Flames - Flammable materials can be ignited by neighboring flames.

Radiant Heat - Nearby burning objects can combust materials without direct contact. Heat can also break windows allowing embers to freely enter.

Flying Embers - Vents and openings allow embers to enter a home and ignite from the inside.

Debris - Combustible materials near the home can ignite and spread the fire.

How Passive House Design Increases Fire Resiliency

Air-tight construction prevents ember infiltration. Minimizing and sealing penetrations means that there’s a low chance for embers to penetrate.

High performance windows are more resistant to heat stress and less likely to break in the event of a fire. Over insulated frames further ensures integrity of the assembly.

Mechanical Ventilation Systems protect the interior from smoke penetration. Air circulation by MVHR is filtered, along with air tight construction, ensures inhabitants are protected from exposure

Simplified Geometry reduces ember accumulation under eaves and nooks. Simplified geometry is a byproduct of not only modern design but also the air tightness principle. Simple geometry makes it easier to insulate, create air-tightness, and eliminate thermal bridges.

Sustainable landscaping is more fire resilient. While not a specific Passive House design detail, sustainability and sustainable landscapes have the added benefit of preventing fire prone debris buildup.

Should We First Consider Passive House When Building in Fire Prone Areas?

There has already been an uptick in interest in Passive House after the Palisades and Eaton fires. However, this is not the first fire that generated significant interest in Passive House design.

Following the Colorado Marshall fire in 2021, there has been an uptick of owners rebuilding with Passive House principles. The 2019-2020 bushfire season in Australia had a similar effect. These two catastrophes lead to the adoption of fire-resilient building codes in Colorado and bushfire codes in Australia. While Passive House is not an outright requirement, there is significant overlap between Passive House design principles and these code requirements.

Passive House construction is typically 10-15% higher than a conventional home. Proponents usually point to energy savings as the reason Passive House may be cheaper or equivalent when considering the total cost of ownership. For those with the means to do so, building to and beyond Passive House standards is a worthwhile consideration.

The place Passive House is already gaining traction in the US is in the north, where existing building stock is old and the temperatures frigid. Massachusetts jurisdictions adopting the stretch code have required Passive House certification since 2023. New York, Colorado, and Washington all allow Passive House energy models as an alternative pathway to code compliance.

Passive House just happens to be more fire resilient, but the benefits stretch far beyond. We have always been the one species that dramatically alters our environment for our comfort. As natural disasters and extreme weather become more commonplace, building better becomes a matter of survival.

For more about Passive House

Passive House Institute is the original and most widely recognized international Passive House certification body centered in Germany.

Passive House Institute US (PHIUS) offers certification for Passive House buildings in North America

Passive House Accelerator is an organization dedicated to education and community building in Passive House and Zero Carbon buildings

Excellent reporting. Nice work.